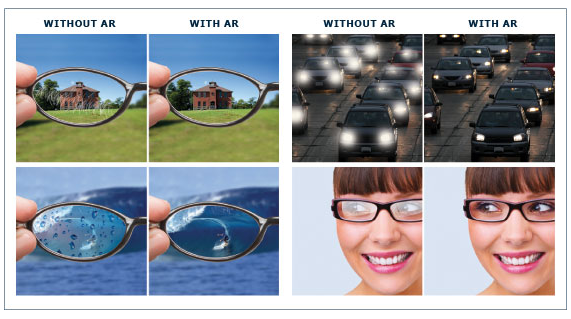

AR coating – anti-reflective coating, or as it is more commonly known as, anti-glare coating – works in two ways: it enhances the vision through your normal eyeglass lenses, while modifying the overall look of your spectacles.

This is due to its ability to remove light reflections from both sides of the lenses, which allows more light to enter the eye through the glass, while allowing the eye to show through the lenses, making it more attractive and visible as it is almost transparent.

Why should you Use AR Coating?

AR coating comes of special use when dealing with a lens of higher refractive index. These lenses are made of a material other than low-index plastic. These are high-index plastic lenses, made of thiourethanes. As such, they have a higher refractive index (which is a property of the refracting material of the eyeglass) and reflect more light – the more the refractive index, the more the light reflected from the surface of the lens.

8% of incident light is reflected back by normal plastic lenses, therefore 92% light is available for the eye’s vision. High-index plastic lenses reflect up to 50% more light than normal plastic lenses (nearly 12% of accessible light), so the image obtained is dim, due to lesser light reaching the eye. This is irksome, not to mention dangerous in low-light conditions, such as driving at night.

Anti-reflective glasses coatings can practically negate the reflection, so that 99.5% of the incident light permeates the lens and reaches the eye. It not only diminishes the glare one sees, but also lessens the glare others see when reflected on the lenses. By doing so, the coating makes the lenses look almost transparent, allowing the face in general to be seen more clearly. These glasses are also more eye-catching, to suit you excellently under all sorts of lighting.

How it’s Made?

A highly elaborate, specialized technique called vacuum deposition technology is used to apply anti-reflective coating to lenses.

- First, the lenses are carefully cleaned, and thoroughly checked for detectable and minuscule surface defects – smudges, lint, fine dust particles, hairline scratches – the presence of even the most infinitesimal faults while coating could result in defects.

- Several washing and rinsing baths, together with ultrasonic cleaning, are done to eradicate all marks of external impurities like oils, invisible stains etc.

- Air drying and warming of the lenses are done in specially-made ovens to completely remove surplus moisture and vapor from the lenses.

- These are then arranged into singular metal racks with spring-operated apertures for the lenses to be secure, with the surfaces exposed for coating. The racks are then packed into the coating chamber.

- The chamber is then sealed and a vacuum is created by flushing out the air with a pump.

- On rotating the racks, a beam of electrons is cast by an electric power source onto a small vessel containing a variety of metallic oxides in individual compartments.

How to Select the AR Coating that is Apt for you?

Every manufacturer possess an exclusive formula, but all anti-glare coatings usually contain several microscopic sheets containing metallic oxides, of fluctuating low and high refractive index. Each layer influences different light wavelengths, so the greater number of layers, the greater amount of reflection that is corrected. A maximum of seven layers can be found in high-quality AR coated lenses.

Your lifestyle determines the type of anti-reflective coating or particular product your optician might prescribe. Suppose, if a huge chunk of your schedule involves you working at a computer, an AR coating that blocks blue light selectively will be of the most advantage. For example, Hoya’s Recharge EX3 anti-glare treatment obstructs strong blue light emanated by electronic devices – phones, computers, e-readers, and even energy-saving light bulbs – that could be detrimental to the eyes over a long period.

Maximum anti-reflective spectacles have a very slight residual color based on the formula used – commonly blue, green or pink – that is typical of that trade name.

Not just for spectacles, but AR coating can also be used for sunglasses, because it eradicates glare from the sunlight reflecting onto the eyes from the back surfaces of tinted lenses when the sun is behind the wearer (usually, only the back surfaces of shaded lenses are coated as there are no visual or cosmetic advantages by removing reflections from the front surfaces).

Premium anti- reflective coating sunglasses also comprise a ‘hydrophobic’ surface layer that repels water and checks formation of water spots, thus making the lenses easier to clean. Some even have an ‘oleophobic’ layer that bounces off skin oils, making smudges on lenses easier to remove.

Know that most of the low-cost AR coatings make the glass lenses hard to clean (anti-reflective coatings are frequently sold as ‘glare protection’, but this from an AR coating is very insignificant. Sufficient glare protection entails a polarized lens, which is available only in darkly tinted lenses).

Image Credits:

allaboutvision.com

stantonoptical.com